References

Introduction of "Quality Round Tables" at Volkswagen

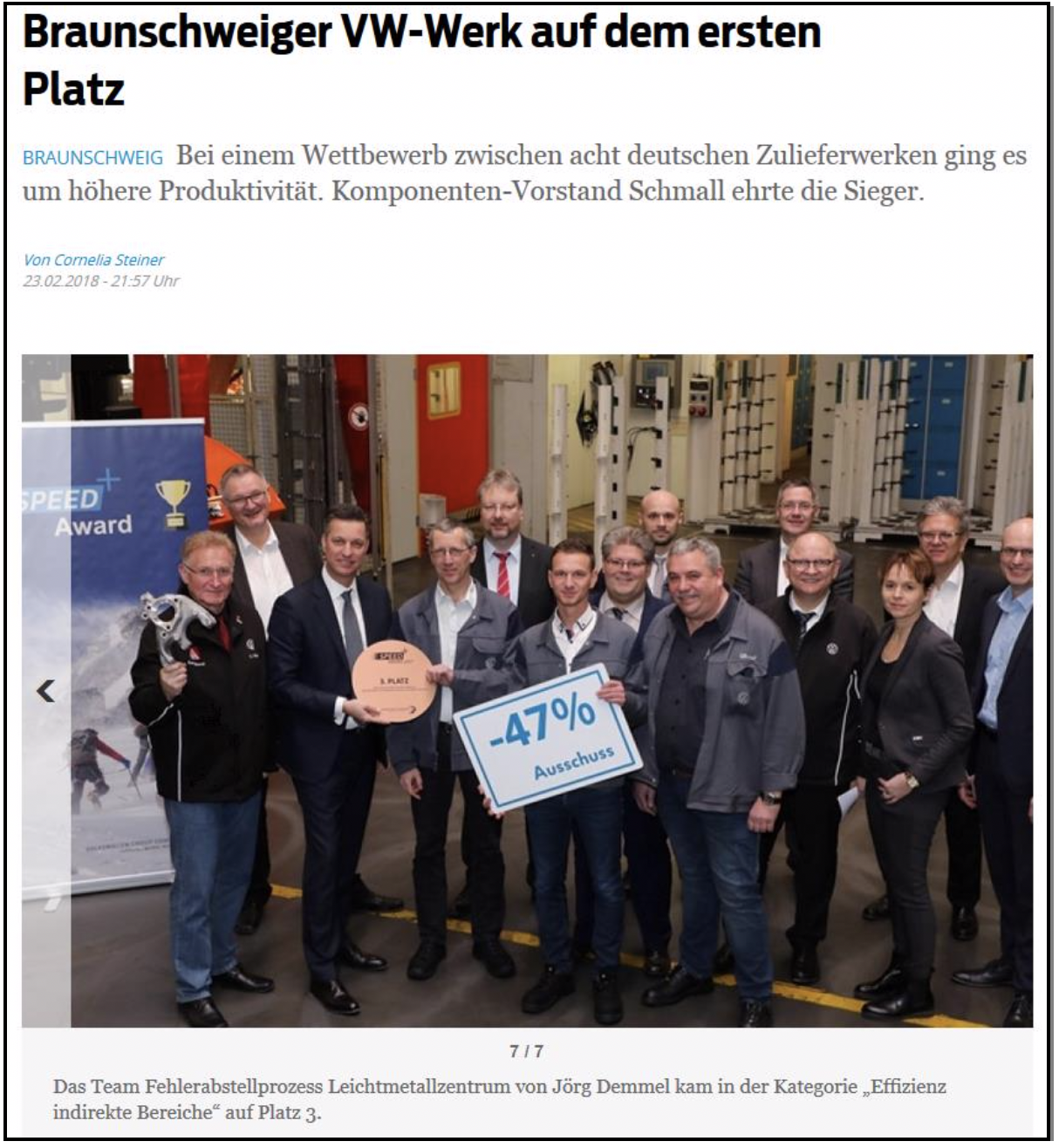

At Volkswagen’s lead chassis and steering plant in Brunswick, I had the opportunity to develop a new shop-floor Quality methodology. Starting with an agreement between the production and Quality departments and the understanding that Quality is the key to success, we introduced so-called “Quality Tables.” Excellent teamwork and high effectiveness saved Volkswagen a lot. The photo shows my one team's result: 47 % less waste in just six months.

Initial Setup of the Quality Assurance at Indigo Technologies

It was an honor to work with Indigo's outstanding team in Boston, Massachusetts, and initiate Quality Assurance from scratch. After an initial Stakeholder Analysis, we followed the AIAG APQP approach and guidelines. As the QA Senior Director, my primary focus was giving Top Management the information needed and empowering the team with effective Quality methods and skills.

Deep Quality understanding enables Innovation for a new Generation of Fixtures

The Fraunhofer Society is the worlds leading applied research organization. For me it was an honor and a great opportunity together with great teammates giving birth to a new generation of Fixtures for heat treatment.

Methods like QFD and FMEA, hard work, and inspiration from the best were essential for effective design and development, risk mitigation, and lastly, the successful market launch of a new class of Fixtures and Racks.

We helped many processes and products for companies like Mann + Hummel, Brose, Huawei.

+ 70 %

Furnace Net Load

- 30 %

Cycle Time

> 500 %

Life Cycle Span

30 %

Savings

Top Reasons Why Choose Us!

What about hiring a Consultant who has worked successfully for many years as a Consultant, an Employee, and an Entrepreneur?

> 30 Years

Experience

25

Happy Clients

What about hiring a Consultant who has worked in different positions and departments at the highest level, such as Design and Development, Planning, QA, and Production?